FLUID BED DRYER

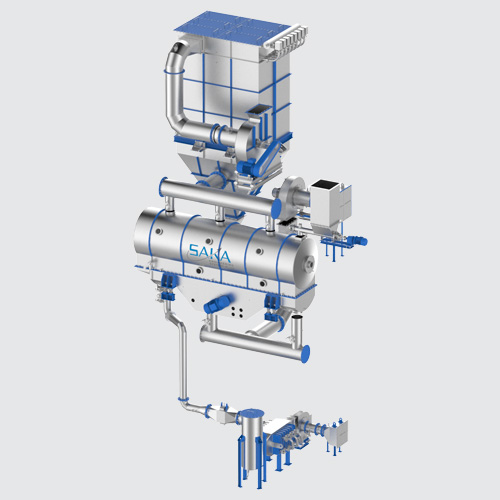

SAKA make Fluid Bed Dryers are ideal for agglomeration, granulation or dry powder formation. Fully customized to meet your specific requirement and trusted by many companies in India and abroad.

CONTROLLED DRYING AND MOISTURE REMOVAL FOR YOUR FEED.

SAKA’s Fluid Bed Dryers (FBD)are specially designed to suit wide range of materials, particle sizes and properties. In a short span of time SAKA has successfully designed and installed a full range of Fluid Bed Dryers, with output from a few hundred kgs per hour to 100 Tonnes Per Day.

Fluid Bed Dryer (FBD) works in continuous or batch type processing. FBD comes with a perforated bed at the bottom. Hot air is blown through this perforated bed causing material to flow in air stream. Hot air is supported with sufficient velocity which causes material to stay in fluidisation state. This causes material to dry while it is in the flow.

Agglomeration

In special cases of Fluid Bed Spray granulation, particulates are built up by spraying liquid on the granules which are in fluidisation state. Particles which are ideal for FBD are pre-processed in steps such as crystallization, coagulation, or polymerization. In some cases dry and wet particles are formed by spray drying prior entering FBD.

FEATURES

- System integration and combination with spray dryer

- Fully automatic PLC/SCADA based system

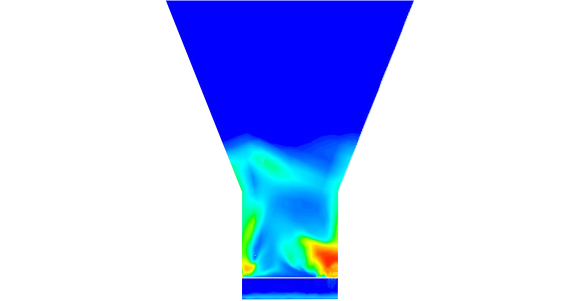

- Tested and Analyzed for performance on CFD

- Good thermal efficiency and energy saving

- Low downtime with minimum maintenance

BENEFITS

- Ideal for moisture removal in powder, crystalline or granular materials

- Proven track record in handling wide variety of materials

- Enhanced heat and mass transfer through close contact and mixing with the fluidizing gas

- Heat sensitive materials can be dried at temperatures lower than the boiling point

SAKA employs highly advanced methodology of Computational Fluid Dynamics (CFD) analysis, to deliver guaranteed results for your Business, Process reliability and system performance. CFD simulation helps to foresee performance before actual execution of the systems, without actual installation of the system. It also helps understand the most vital parameters for improving performance..

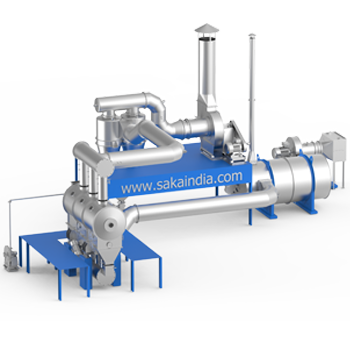

VIBRATORY FLUID BED DRYER

Controlled drying with continuous processing

Vibratory Fluid Bed Dryer are used for mass heat transfer and have relative smaller residence time. SAKA’s Vibratory Fluid Bed Dryers are known for its versatile applicability with a ability to process wet as well as semi wet products.

Vibratory motion in this type FBD’s moves the product through Dryer. Usually a push-pull system is used to balance the pressure to slightly negative in the free board of the fluid bed. Depending upon the product and available heat source, direct or indirect heating may be applied. Then the exhaust air is cleaned by bag filter, cyclone with or without wet scrubber.

SAKA’s Vibratory Fluid Bed Dryer are known for maintaining equilibrium of thermal efficiency and moisture content of the material thus ensuring effective, efficient and controlled drying.

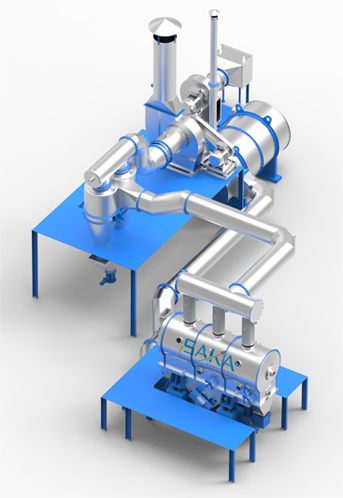

ADVANCED DRYING SYSTEM

Achieve the best efficiency with advanced drying system

Apart from Fluid Bed Dryer and Continuous Fluid Bed Dryer, SAKA also provides advanced double stage and multi stage drying solutions.

Double stage drying is a combination of Spray Dryer and Fluid bed or Vibrating bed dryer. Here moisture content after spray drying is relative higher as compared to single stage. After spray drying moisture content is further reduced in second stage where it passes through Fluid Bed Dryer or Vibrating Bed Dryer. Double stage drying enables drying at relatively lower temperature making it suitable for heat sensitive materials and also avoids its degradation.

KEY PROJECTS

Type: Vibratory Fluid Bed Dryer

Capacity: 1000 kg/hr

Installed at: Meerut, UP

Type: Vibratory Fluid Bed Dryer

Capacity: 2500 kg/hr

Installed at: Punjab

Type: Vibratory Fluid Bed Dryer

Capacity: 2500 kg/hr

Installed at: Bharuch, Gujarat

3D Fluidization In FBD

CFD analysis of Fluidized bed dryer for Hot air Distribution

APPLICATIONS

Polymers and Resins | Organic and Inorganic Chemicals | Chemicals

Pharmaceuticals | Coffee | Dairy | Fertilizers | Food

-

Client 01

Client 01 -

Client 02

Client 02 -

Client 03

Client 03 -

Client 04

Client 04 -

Client 05

Client 05 -

Client 06

Client 06 -

Client 07

Client 07