SPRAY DRYERS

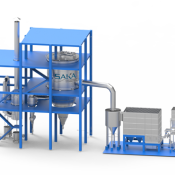

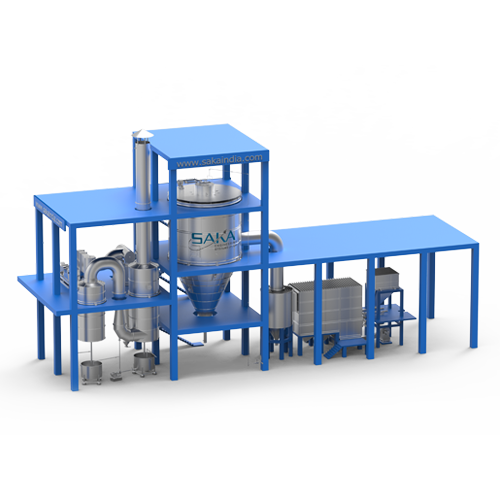

With deep process expertise, Advanced CFD simulation and highest manufacturing quality SAKA offers most advanced Spray Drying technology available in the market.

TOTAL CONTROL OVER DRYING PROCESS

SAKA’s Spray Dryers are designed to serve your specific process needs to deliver best output efficiency, with optimum operational costs and no product wastage.

The Spray dryers are designed based on inputs derived from in-depth analysis of your process parameters, available space and the application. Engineering and automation in SAKA’s Spray Dryers provide you with complete control on configuring key process characteristics such as moisture content, particle size, bulk density, flow patterns etc. to manufacture the desired product.

With an installed base of over hundred Spray Dryers, delivered in just seven years, SAKA is also credited with successful installation of one of the biggest Spray Drying plant in India at Bhavnagar, Gujarat.

ADVANTAGE

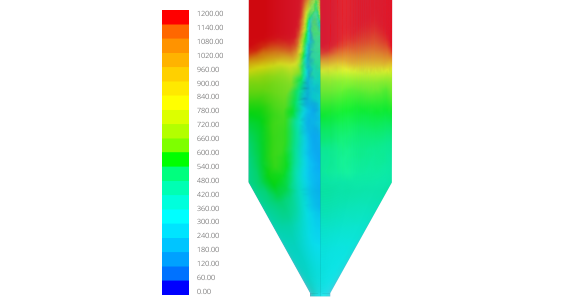

- Proven designs tested with CFD analysis

- Capability

to design, manufacture and commission dryer for any capacity

- Strong process expertise with world class quality

- Experienced team of service engineers to provide you continuous support

- Highly energy efficient with lesser cleaning and maintenance

BENEFITS

- Works perfectly on any type of feed abrasive, corrosive, flammable,

explosive or toxic - Total control over product density and particle size

- Powder quality remains consistent during the entire run

- Good suspension and dispersion properties

SAKA employs highly advanced methodology of Computational Fluid Dynamics (CFD) analysis, to deliver guaranteed results for your Business, Process reliability and system performance. CFD simulation helps to foresee performance before actual execution of the systems, without actual installation of the system. It also helps understand the most vital parameters for improving performance.

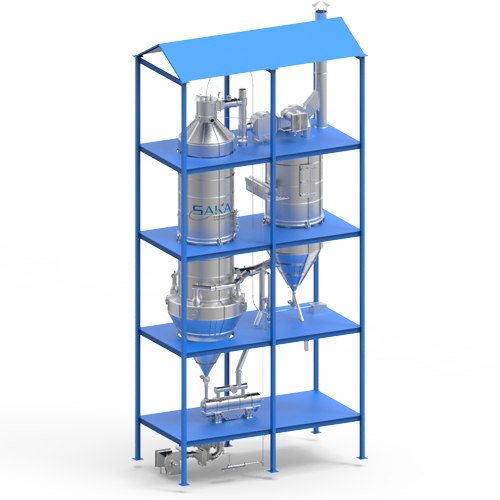

CO-CURRENT SPRAY DRYER

Effective drying for heat sensitive material

In co-current spray dryers, feed and hot air are introduced in chamber to travel in same direction.

this type of drying process is ideal for heat sensitive material such as Dairy, Food or Fruit extracts as product does not suffer heat degradation.

Here feed comes in contact of warm air at its highest temperature. At the same time feed has very high moisture content. Moisture content of feed gradually gets reduced so does the temperature of the hot air leading controlled drying.

COUNTER CURRENT SPRAY DRYER

Rapid drying with higher thermal efficiency

In these type of Dryers, air and feed are introduced from opposite directions. Feed is introduced from the top and hot air is introduced from the bottom.Counter Current Dryers have better efficiency and output, but are not ideal for heat sensitive material. Typically, these type of Dryers are ideal for products like Soaps, Dyestuff, Detergents etc.

Here feed first comes in contact of warm at its lowest temperature and gradually gets exposed to the hotter air. Counter Current Dryers are more effective and have better thermal efficiency then that of a Co-current Spray Dryer.

MIXED FLOW SPRAY DRYER

Superior performance with better mixing process

This is a combination type of air flow system i.e. Counter as well as Co-current. Here Air is introduced from the top and atomizer is located at the bottom, thus providing mixed flow effect. This type of drying is slightly identical to counter current hence it is not applicable for heat sensitive material.

SPRAY DRYER WITH NOZZLE OPERATION

Uniform particle formation with effective drying

In case of Spray Dryer with Nozzle, Dryer comes with a spray nozzle which facilitates formation of fine droplets at very high speed. These kind of Dryers are used where faster evaporation of heat is required.

Here feed is introduced in drying chamber through a high pressure nozzles forming small droplets. These fine droplets get dried immediately as soon as they come in contact of hot air.

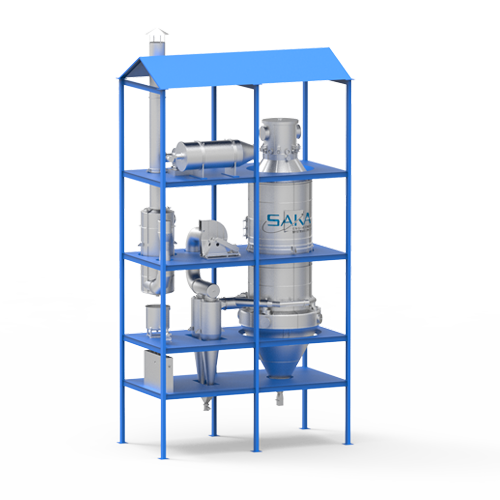

SPRAY DRYER WITH ROTARY ATOMIZER

Instant drying with high speed dispersion

Spray dryers with Rotary Disc Atomizers from SAKA are capable to handle material in large quantities and any viscosity. Wheel design is customized according to powder characteristics. Ideal for applications like herbal extracts, ceramics, inorganic chemicals and dye stuffs , these Spray Dryers are used where liquid feed is required to converted into fine droplets.

Feed is introduced through a high speed rotating disc which throws liquid outward at very high velocity. This leads formation of fine droplets which are dispersed on the walls of the spray dryer. these droplets when comes in the of hot air/gas to form dry solids, granulate or agglomerate particles

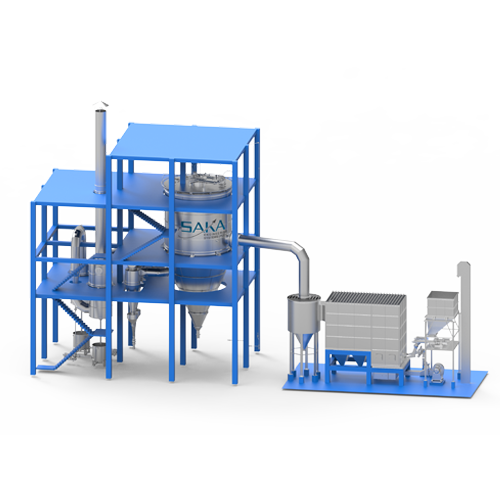

ADVANCED DRYING SYSTEM

Achieve the best efficiency with advanced drying system

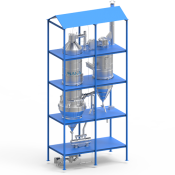

Apart from Single Stage Spray Drying, SAKA also provides advanced double stage and multi stage drying solutions.

Double stage drying a combination of Spray Dryer and Fluid Bed or Vibrating Bed Dryer. Here moisture content after spray drying is relative higher as compared to single stage. After spray drying moisture content is further reduced in second stage where it passes through Fluid Bed Dryer or Vibrating Bed Dryer. Double stage drying enables drying at relatively lower temperature making it suitable for heat sensitive materials and also avoids its degradation.

Maintenance Procedure for Rotary Disc Atomiser

APPLICATION

Dyestuffs | Pigments | Food processing | Starch | Detergents | Pharmaceutical | Herbal Extracts | Food Flavors | Ceramics & China Clay

-

Client 01

Client 01 -

Client 02

Client 02 -

Client 03

Client 03 -

Client 04

Client 04 -

Client 05

Client 05 -

Client 06

Client 06 -

Client 07

Client 07