GRANULATION SYSTEMS

Managing your Hydrochloric Acid Bi-product is now profitable and easy, get Calcium chloride granules with SAKA’s fully automatic granulation system

GET FREE FLOWING CALCIUM CHLORIDE GRANULES FROM THE LIQUID FEED

Handling, managing and disposing Hydrochloric Acid (HCL) is one of the cumbersome task. Many companies in process industry, end up manufacturing HCL as bi-product.

HCL is not only hazardous but also has acute side effect on human body. Effective disposing of HCL is costly and difficult. HCL can be further processed to form Calcium Chloride which has a wide industrial applications and demand.

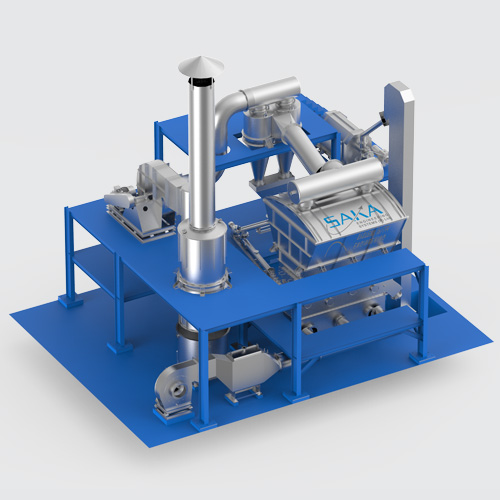

SAKA offers complete turn key solution for Granulation systems right from drying till packing of Granules. Our systems are widely used for granule formation for chemicals like Calcium Chloride, Magnesium Chloride, Calcium Nitrate etc. SAKA’s Granulation systems are custom built to provide desired size of granules.

Our systems can convert various types of raw materials into free flowing and dust free granules such as aqueous solutions, emulsions or suspensions. Beside this, waxes and other fusible raw materials can be processed in our Granulation system. These types of materials are processed as melts, melt emulsions or melt suspensions to produce granulates.

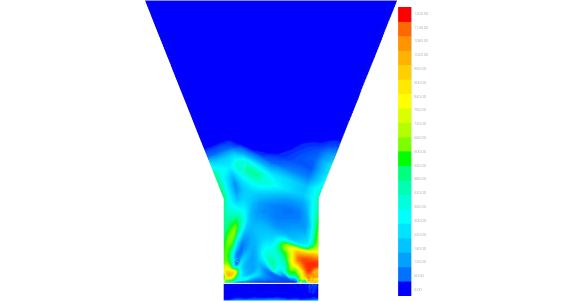

Being probably only Indian company manufacturing Calcium Chloride granulation Plant, SAKA’s Granulation plants are tested on advanced CFD analysis ensuring better performance and output efficiency.

FEATURES

- Fully Automated PLC/Scada based granulation plant

- Abrasion and corrosion resistant manufacturing

- Auto cleaning facility with retractable nozzles

- Strong and sturdy construction

BENEFITS

- Defined particle size for effective granulation

- No need to keep track of HCL disposing

- Excellent utilization of bi-product Hydrochloric Acid

- Free-flowing, non-dusty particles

SAKA employs highly advanced methodology of Computational Fluid Dynamics (CFD) analysis, to deliver guaranteed results for your Business, Process reliability and system performance. CFD simulation helps to foresee performance before actual execution of the systems, without actual installation of the system. It also helps understand the most vital parameters for improving performance.

ACHIVE THE BEST EFFICIENCY

WITH ADVANCED DRYING SYSTEM

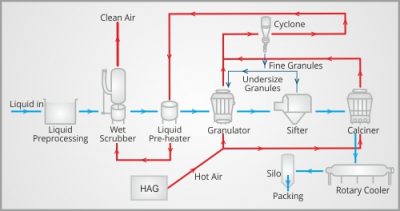

Hot Air Generation – HAG generates hot air using indirect/direct heating

Preparing fluid bed dryer – Fluid Bed Dryer is fed with granules from the earlier cycle/recycle. it has perforated plate at the bottom with specific holes for effective fluidisation

Feed Introduction – Calcium Chloride liquid is sprayed over the granules which are in fluidisation state

Fluidisation – Liquid forms a layer/coating over the granules which get dried as soon as it comes in contact of warm air

Granule formation – This leads to increase in size of the granules

Granules Output – As the quantity inside the Fluid Bed Dryer increases it overflow through a a rotary air lock valve.

Sifter – The output product is made to pass through a sifter which segregates the granules based on there size.

Recycle – smaller particles are reintroduced for fluidisation in the granulator

Calcination – right sized particles are further carried to the Calciner for removal of moisture which increases product purity

Final Granules – Hot granules are further passed through cooler

Storage & Packing – Transfer of final Calcium Chloride granules to storage silo and packing

APPLICATIONS OF CALCIUM CHLORIDE GRANULES

Oil and Gas | Construction | Road | Paint | Fire fighting | Food

Fabric | Automotive | Mining | Paper

SAKA GRANULATION SYSTEMS ARE ALSO AVAILABLE FOR

Sodium benzoate | Calcium nitrate

-

Client 01

Client 01 -

Client 02

Client 02 -

Client 03

Client 03 -

Client 04

Client 04 -

Client 05

Client 05 -

Client 06

Client 06 -

Client 07

Client 07