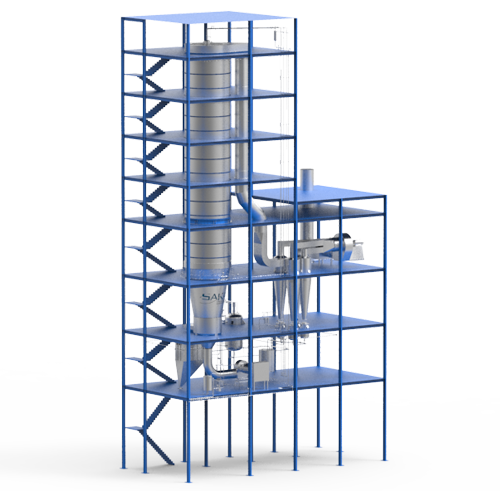

ZERO LIQUID DISCHARGE PLANTS

Unique Spray Dryer based Zero Liquid Discharge systems for hassle free processing of effluents to ensure reliable and responsible cleaning.

RELIABLE AND RESPONSIBLE ZERO LIQUID DISCHARGE SYSTEMS FOR CLEAN ENVIRONMENT

Efficient handling of effluents one of the biggest challenge when it comes chemical industry. It becomes even more important when it comes to environmental impacts and statutory norms. With increasing awareness about environment, Need of Zero Liquid Discharge Plants (ZLD) has increased phenomenally.

SAKA is known for its advanced and innovative solution when it comes Dryers, Congealers and Granulation plants. SAKA make ZLD is a similar unique innovation which completely based on Spray drying technology , eliminating the need of Evaporator. This reduces the capex by almost 50% We have successfully installed many plants in Maharashtra and Gujarat which are performing flawlessly for last couple of years.

We have made many advancements in the ZLD to ensure maximum utilization of the heat and minimum wastage. Most of the times, furnace oil, liquid oil or gas is used for generation of heat. At SAKA we have used fuel like biomass or coal which is extremely cheap as compared to liquid fuels.

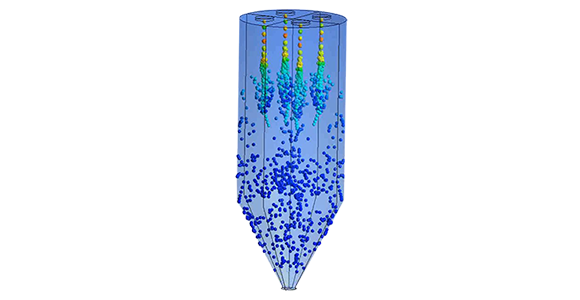

SAKA employs highly advanced methodology of CFD analysis, using cutting-edge tools to deliver guaranteed results for your business. Process efficiency, reliability and system performance. CFD simulation helps to foresee performance before adapting or execution in systems. Without installing real system or a pilot, CFD simulation helps understand the most vital parameters for improving performance

SPRAY COOLER

efficient performance with ease of operation

Spray cooler or congealers are ideal solution for processing organic chemical, food and heat sensitive material. SAKA spray coolers are highly regarded for their efficient and effective processing. Manufactured with latest technology and best quality raw materials our coolers are extremely easy to operate and maintain.

Known for it’s capability to process very fine particles Spray coolers from SAKA can process coarse particle products with mean particle size of 50-150 micron. In case specialised requirement a second stage of processing can also be provided with FBD or pneumatic conveying system.

Environmental norms are one of important factor when it comes to spray cooling; SAKA’s expert team ensures that our coolers stay well within these norms.

ROTARY COOLER

long lasting and consistent performance

Rotary coolers from SAKA are known for their long lasting and consistent performance. SAKA has built a strong capability to design and develop customized rotary coolers as per specific requirement. Whether you require short or long residence times, chilled or ambient cooling air, carbon steel or specialty steels, we can design a rotary cooler for your application and analyze its performance well before manufacturing.

Rotary coolers have heavy-duty drum construction. This makes it ideal for wide range of applications and large capacity processing for both drying and cooling procedures.

Typically, Rotary coolers work on the principle of coiunter current air flow where chilled or ambient air comes first in contact with material at its highest temperature leading to efficiently cool material. Additionally, flights lift and cascade material through the drum, enhancing the cooling process.

FLUID BED COOLER

100% moisture removal from the feed

Fluid Bed Cooler from SAKA offers a series of advantages such as homogeneous mixing, lower fluidising velocity, lesser energy consumption. Fluid Bed Collere

use ambient or cool air/gas to dry the feed. These type of coolers are ideal for removal of the last trace of moisture from the feed.

Fluid Bed Cooler is a moduler type of cooling solution, Similar to Fluid Bed Dryer, Coolers also keep material in Fluidization state with the help of air or gas. This leads to the entire surface area of the material to get exposed while it is suspended , increasing cooling efficiency.

Use of Cool air means drying without any degradation of the product, this making it ideal for heat sensitive materials. fLUID BED COOLERs can work efffectively in continuous as well as batch type processing. Using fluid bed cooler in close loop helps to increase solvent or gas recovery.

APPLICATIONS

Chemicals | Food | Pharmaceuticals | Minerals

Fertilizers | Industrial Waste | Limestone

-

Client 01

Client 01 -

Client 02

Client 02 -

Client 03

Client 03 -

Client 04

Client 04 -

Client 05

Client 05 -

Client 06

Client 06 -

Client 07

Client 07