ALLIED PRODUCTS

known for its trouble free and consistent performance SAKA’s allied products ensures that your process plant runs smoothly with any hassle.

PROVEN TECHNOLOGY RELIABLE PERFORMANCE

SAKA has a wide range of allied products right from rotary valve to blowers and heat exchangers. Known to demonstrate an unparalleled performance and efficiency, SAKA’s allied products has earned a high reputation among the clients cutting across wide range of applications and industries.

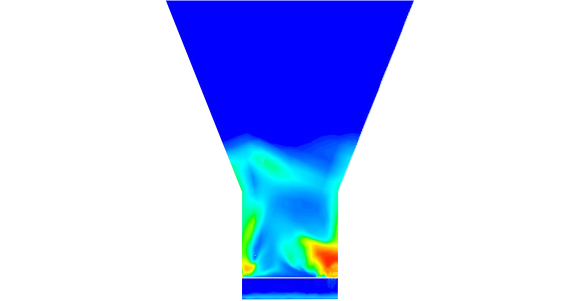

A deep Knowledge of the customer’s processes, Through understanding of applications and strong engineering expertise are pivotal to SAKA’s product design. Every step in SAKA’s process, be it CFD analysis, material selection or quality and testing, is aligned to meet the customer’s goals in productivity, end product specifications and EHS norms. Highest quality of materials and advanced technology are the hallmarks of our systems.

SAKA employs highly advanced methodology of Computational Fluid Dynamics (CFD) analysis, to deliver guaranteed results for your Business, Process reliability and system performance. CFD simulation helps to foresee performance before actual execution of the systems, without actual installation of the system. It also helps understand the most vital parameters for improving performance.

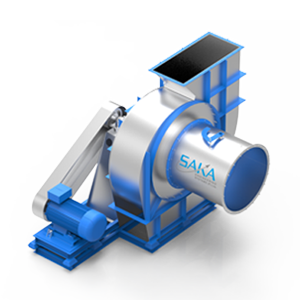

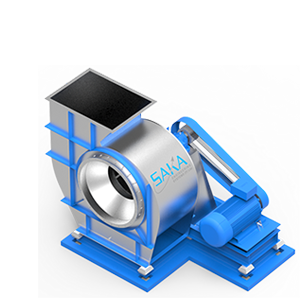

BLOWERS

Maximum velocity, optimum energy consumption

No matter how big or small is the air handling requirement for your process, SAKA’s specialist range of industrial blowers are designed to perfectly meet the needs in air flow capacity, velocity, coverage and energy consumption. SAKA’s Industrial blowers are known for dust handling design and sturdy construction. Manufactured with Australian collaboration, our blowers are made from exotic raw material making it ideal for wide range of industrial applications.

Benefits

- Dust handling designs

- Made from exotic raw materials

- Technical support for blower selection

- Over designed fans without increase in power consumption

- Excellent testing facilities

- Tested for performance by unique CFD analysis technique

Forced Draft Blower

Forced Draft Blowers are ideal when positive and controlled pressure is to be maintained in the system. SAKA’s specialties include thoroughly analyzed, proven designs that achieve ideal performance across diverse process applications.

Indirect Draft Blower

Induced Draft Blowers use negative pressure to pull the air in the system, thus creating a pneumatic force that moves the material. SAKA’s Induced Draft Blowers are designed and engineered to offer a superior performance, consistently

ROTARY DISC ATOMIZERS

Ensuring perfect particle formation

Rotary disc atomizers are ideal for material which are viscous or very abrasive in nature. These atomizers come with a perforated disc which rotates at very high speed, large flow rates and provide homogeneous spray. The feed is introduced through this rotating disc which throws the liquid outward, at very high velocities to create formation of fine droplets.

In-depth analysis of Rotary Disc Atomizer designs using advanced CFD analysis means an assured performance and long life when put to use.

RANGE: A60 /A100/A150/A250/A300/A350

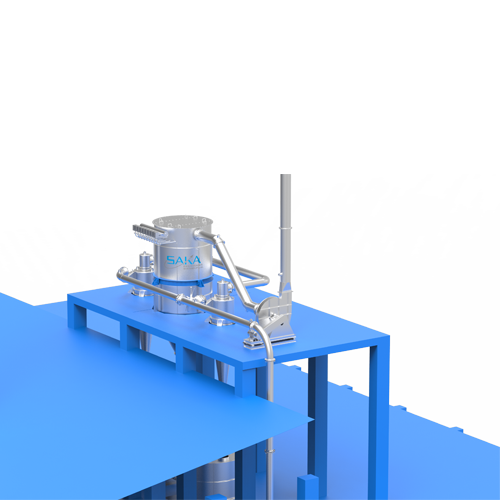

PNEUMATIC CONVEYOR

Bulk material movement made easy

Pneumatic conveyors use air as a force to transfer the material. The quantum of force to be applied depends on the product and its properties. Since hot or cold air can be used in the pneumatic conveyors, additional drying or cooling effect can be provided.

SAKA’s pneumatic conveyors can be used with spray dryers and best result can be achieved if ambient air is used giving dual effect of conveying as well as cooling the material.

- Anti-static system for magnetic powders

- Explosion protection

- Least product attrition

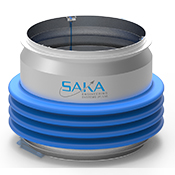

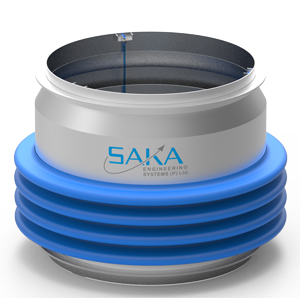

EXPANSION DUCT

ensuring zero wastage of heat & amp material

Expansion ducts, also known as expansion bellows or joints, are used at the ducts which are prone to get damaged due to thermal growth, vibration, pressure thrust and other mechanical forces. SAKA’s flexible steel make expansion ducts are tested for performance using extensive CFD analysis thereby assuring good quality and zero wastage of material or heat due to leakage. Sturdy construction means the bellows can withstand the pressure, thermal growth as well as vibration during process ensuring the safety of material and operators.

- Available in large sizes (350mm to 2 m)

- Engineering assistance for designing and installation of expansion duct

SCREW FEEDER

Modular construction, effective operation

SAKA’s Screw Feeders come with modular designs which caters to special material conveying requirement in free flowing dry powders, grains, to semi-fluid materials. The Screw Feeders from SAKA are used in diverse industries such as Glass, Soap & Detergent, Welding electrode, Chemical, Minerals Processing, Food, etc.

SAKA’s screw Feeder is designed for continuous and flowing pick up from material hopper. Manufactured with greater pitch spacing, SAKA’s screw conveyors deliver more carrying capacity without increasing rotation.

- Available in carbon steel, abrasion-resistant steels, stainless steel and high-nickel steel

- Anti Choking design

- Greater pitch spacing

HEAT EXCHANGERS

Transferring high efficiency heat

SAKA offers complete range of heat exchangers, used for providing warm air to Dryers, Evaporators, Ovens many other applications. Known for high thermal efficiency, proper insulation our heat exchangers comes with direct and indirect type. Using steam, oil and electricity as fuel SAKA make heat exchanger are capable to provide consistent heat through out the process.

- Unique expansion arrangement or longer life

- Integrated fin design for highest efficiency

- Corrosion resistant construction

- Low pressure drop

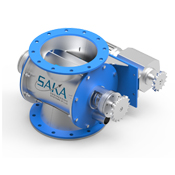

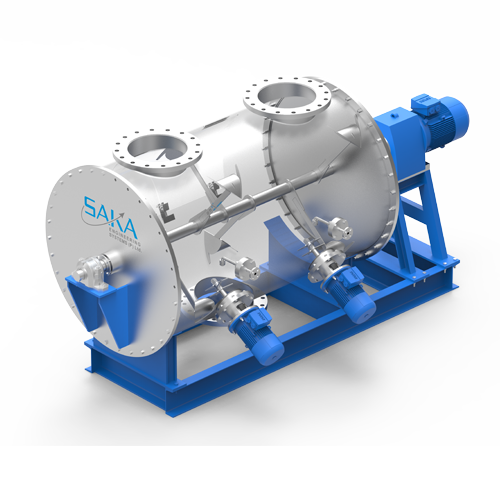

ROTARY VALVES

Superior performance in extreme conditions

Choose from SAKA’s wide range of Rotary Valves. Known for their superior performance our rotary valves can operate even in extreme condition. Manufactured from best quality raw materials as well as stringent quality standards means assured efficiency and best control over the flow process.

Rotary Valve is a compact mechanical device to regulate the flow of a material from one chamber to another continuously, while maintaining a good airlock condition.

- Optimum efficiency with very low maintenance

- Analysed for performance on CFD analysis technique even before execution

- Sturdy construction

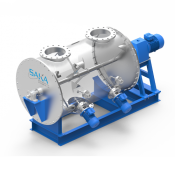

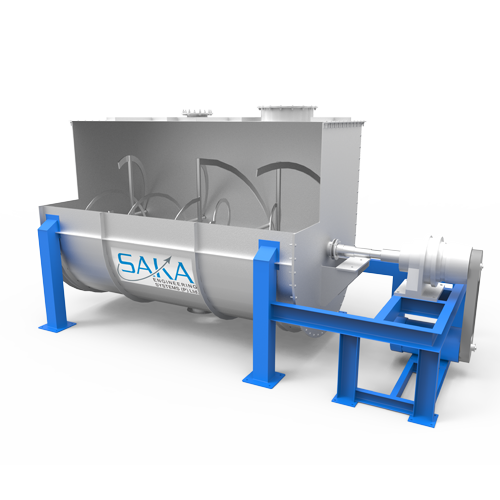

BLENDERS

Benchmark performance, reliable output efficiency

SAKA Make Blenders are known for their premium quality that are ideal for blending of various type of material.

Fast, uniform and efficient blending are few of the most important features of our Blenders.

SAKA’s Blenders comes with U shaped truck and helical ribbons which ensure perfect mixing of various ingredients

Available in various sizes and capacity our blenders are corrosion resistance, sturdy and durable.

PLAUGH MIXER

Homogeneous and effective product mixing

SAKA’s plaugh mixers are well known in the industry for it homogeneous product mixing and high efficiency.

Manufactured from finest quality raw material our plaugh mixers are safe and extremely easy to operate.

Capable to blend dry as well as granules our plaugh mixers can also mix products with lower viscosity without adding liquids.

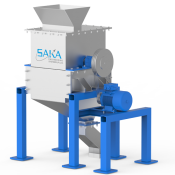

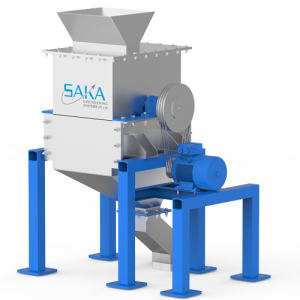

COAL CRUSHER

Optimum space, maximum space

Coal crushers are used to reduce the size of the coal for further preparation or used as fuel for boilers, HAG etc.

SAKA’s coal crushers are known for converting coal into specific size as per requirement. With option of hydraulic, electrical and automatic operation our coal crushers are very easy to use.

- Heavy duty coal crushers

- Designed and manufactured to suit customize crushing requirement

BUCKET ELEVATOR

Optimum space, maximum space

Bucket elevator is ideal solution for vertical transportation of material such as grains, coal, pellets , powder etc. Bucket elevators from SAKA are known for their low energy consumption and extremely safe operation. Manufactured with high quality steel our bucket elevators can transport wide range of material in gentle manner.

- Available in SS and MS steel

- Modular design and sturdy construction

- Better efficiency with less power consumption

Thermal and Structural analysis of Metallic Expansion bellows

APPLICATIONS OF CALCIUM CHLORIDE GRANULES

Dyestuffs | Pigments | Food Processing | Starch | Detergents | Pharmaceutical | Herbal Extracts | Food Flavors | Ceramics & China Clay

-

Client 01

Client 01 -

Client 02

Client 02 -

Client 03

Client 03 -

Client 04

Client 04 -

Client 05

Client 05 -

Client 06

Client 06 -

Client 07

Client 07